Simple Heat Treatments

Jun.28,2017

Four simple heat treatments are commonly used for steels. These heat treatments(Fig.1-7-3) are used to accomplish one of three purposes.

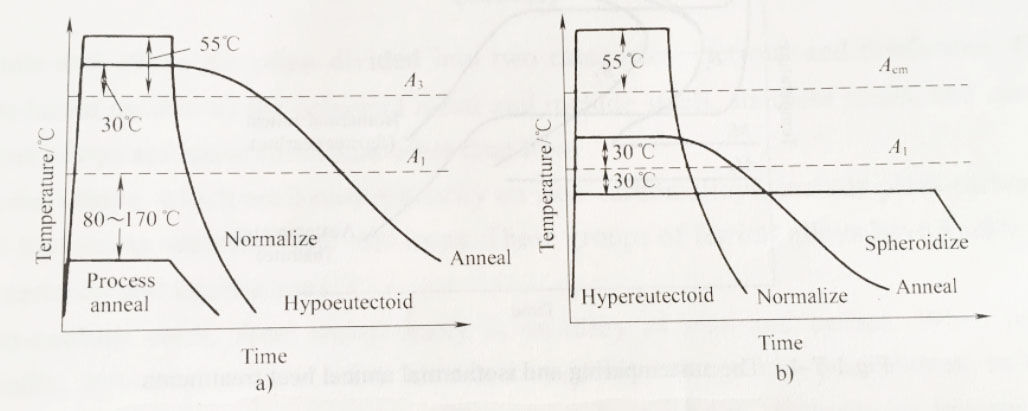

Process anneal-eliminating cold work. The ferrite in steels with less than 0.25% carbon is strengthened by cold working. The recrystallization heat treatment used to eliminate the effect of cold working is called a process anneal. The process anneal is done 80℃ to 170℃ below the A1 temperature.

Annealing and normalizing –controlling dispersion strengthening. Plain carbon steels are dispersion strengthened by controlling the amount, size, shape, and distribution of Fe3c. As the carbon increases, more Fe3C is present and, up to a point, the strength of the steel increases.

We can refine the Fe3C by controlling the cooling rate as the austenite transforms to pearlite. If we permit very slow cooling, the pearlite is coarse-this heat treatment is called annealing or a full anneal. Faster cooling produces fine pearlite-this heat treatment is normalizing.

Spheroidizing-improving machinability. High-carbon steels, which contain a large amount of Fe3C,have poor machining characteristics. During the spheroidizing treatment, which requires long times at about 30℃ below the A1, the Fe3C changes into spherical particles in order to reduce boundary area. The microstructure, known as spheroidite, now has a continuous matrix of soft, machinable ferrite. After machining, the steel is given a more sophisticated heat treatment to produce the required properties.

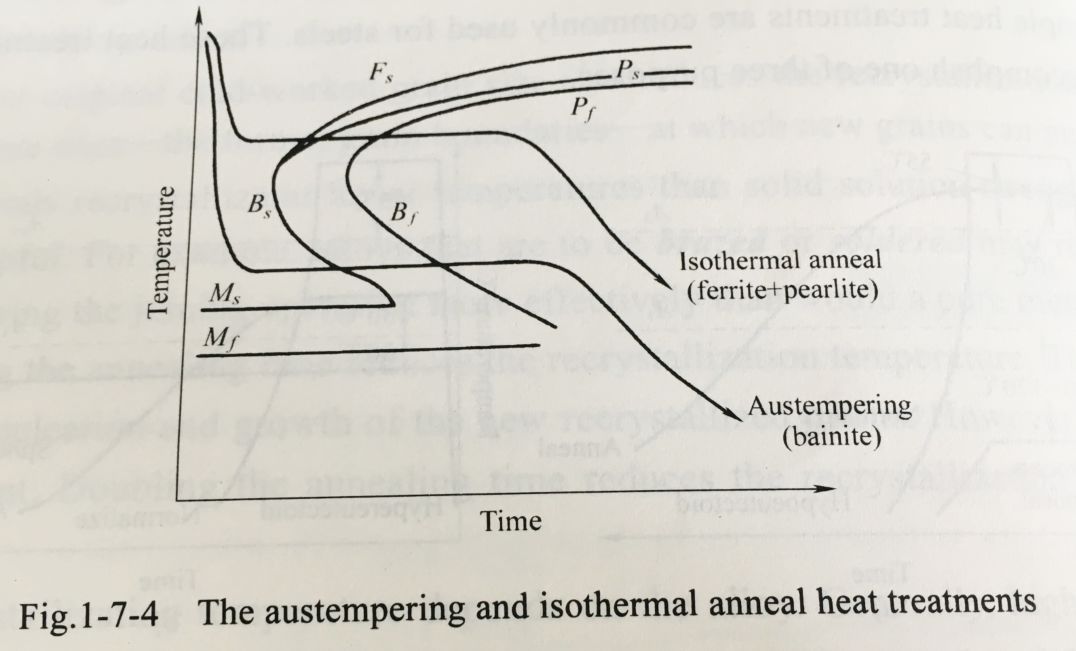

Austempering and isothermal annealing. The isothermal transformation heat treatment used to produce bainite is called austempering, and simply involves austenitizing the steel, quenching to some temperature below the nose of the TTT curve, and holding at that temperature until all of the austenite transforms to bainite(Fig.1-7-4).

Annealing and normalizing are usually used to control the fineness of pearlite. However, pearlite formed by an isothermal anneal(Fig.1-7-4)may give more uniform properties,since the cooling rates and microstructure obtained during annealing and normalizing vary across the cross section of the steel.